Process & Control Automation

From project management, to control panel manufacturer, hygiene, and quality control, we can manage the process from design to installation and commissioning.

Industrial automation has typically been costly and complex, best suited to high-volume industries such as FMCG or automotive manufacturing. However, a new category of affordable industrial robotics is making automation more accessible for SMEs than ever before.

Industries we can help with

Food And Drink

Food processing plant design consultants can help you improve your plant’s energy efficiency, increase your rate of production, reduce lead times, and achieve 100 percent food safety compliance. However, they are also essential when you want to expand your operations.

Pet Food

Setting up a pet food production line is similar to a human food production line. However, as you might expect, there are some differences.

Pharmaceutical

Pharmaceutical engineering and plant design consultants help you expand pharmaceutical production lines in factories more efficiently and effectively. Their work includes regulatory compliance, validation, and implementing logistics services for maintenance and systems management. Most consultants assist firms from the initial concept stage onwards, guiding them through every step of the plan.

Petrochemical

Using an outside consultant for your petrochemical engineering projects can help you to maintain safety, efficiency and productivity like never before, all while minimising your spend and controlling your budget for your petrochemical plant construction.

Process and Control Automation

By implementing a low-cost robotic automation solution, food SMEs can easily address key bottlenecks in production lines, maintain flexibility around capacity and throughput, increase volumes to meet temporary spikes in customer demand, and free up staff and upskill them for more value-added work.

- Control panels: All our bespoke control panels are built in our factory. We can fit HMI – Scada facilities in them if required. All programmes are uniquely written for your process, and on-off site support is provided. The control panels can be manufactured in stainless or metal (powder coated). All field wiring can be included with in the packages.

With our vast experience in process control, we can provide specific services aimed at reducing costs, time, and resource to increase productivity and efficiency including:

Conveyor systems:

Our expert conveyor manufacturers and food process engineers are ready to design, build and install any conveying transport system you may need. We only use the best quality parts inclusive of SEW drives and Rodriguez stainless steel bearings. We will lead on the design of the conveyors inclusive of the belting required for the application.

Typical examples of conveyor systems include:

- Elevator conveyors

- Multi-head, easy clean conveyors

- Radius conveyors

- Screwed conveyor

- Pneumatically retracting conveyors

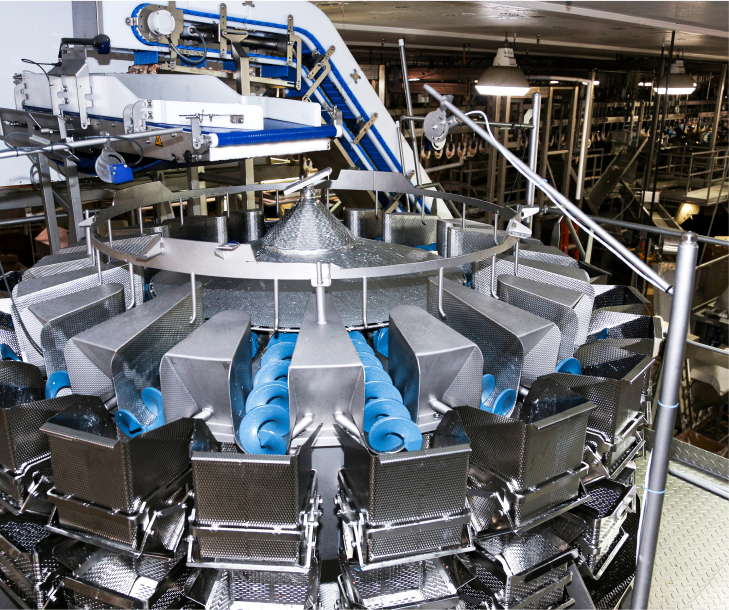

Multihead weighers:

We have teamed up with a specialist multi-head weigher company, Ishida to supply entry-level to high-specification models which combine high-speed operations with unparalleled accuracy and reliability. The Multihead weighers can be installed as part of an integrated weighing and packing line or interfaced with existing packing equipment.

Multihead weighers are pivotal to improving efficiency and consistency on the production line with:

Improved weighing accuracy means more packs per kg of product. Fast calculation time delivers more packs per shift.

- Self-tuning vibration system optimises product flow

- Simple, tool-free cleaning cuts weighing machine downtime Quicker

- Simpler training and use, with an easy-to-learn operator interface.

- A range of ‘bolt-on’ options is available

Automation:

- Hygiene Equipment: We can provide you with a unique selection of wash basins from boot washes, and equipment cleaning, to our own Steri-Fess automated hand sanitiser units. These compact anti-virus sanitising units are perfect for high footfall areas.

- Quality Control: We can supply and install a variety of check weighers, metal detectors, x-ray machines, and seal integrity Testers.

- Pick and place: Our robotic pick and place systems are unique and bespoke to your requirements. As small and medium-sized manufacturers face increasing pressure to remain competitive by improving margins and efficiency whilst facing skills shortages, robotics can be an effective part of the solution to your challenges.

- Metal Detection: Our extensive knowledge and experience in X-ray, inspection systems, and metal detection offer the ultimate solution to help protect you, and your customers and safeguard your brand.

Frequently Asked Questions

The two main types of industrial automation are fixed automation and programmable automation. Fixed systems are designed to carry out one set of tasks over and over again. They are mostly used for mass production or continuous flow systems like automated belt conveyor solutions.Programmable systems use a computer program to provide commands, meaning the automated processes can vary based on the computer’s instructions. This type of automation is often found in operations where multiple items are created using the same equipment and steps with little to no variation. An example of this is paper and steel rolling mills, which utilise the same method to produce a number of different product types.

Conveyers will normally be made up of a belt stretched across multiple pulleys that create a closed loop in order to rotate. One pulley in the system (the drive pulley) controls the direction of the belt, ensuring items are successfully moved from one part of the factory to another. The majority of system designs utilise a rotor to power the belt and driver pulley. Conveyor systems are often straight like food processing conveyor belts for example but can be adapted to include a turn where necessary using cone-shaped wheels or rotors.

A multihead weigher is designed to divide bulk quantities of products into smaller increments based on the limits you have defined in your software. It is an extremely beneficial piece of equipment in food engineering as it can accurately divide materials into the right amounts at fast speeds. It can reach significantly higher speeds than a manual weigher and save you time by automating the entire process.

Mechanical and Electrical Services

Mechanical and Electrical Services  Lift and Shifts Works

Lift and Shifts Works  Construction

Construction