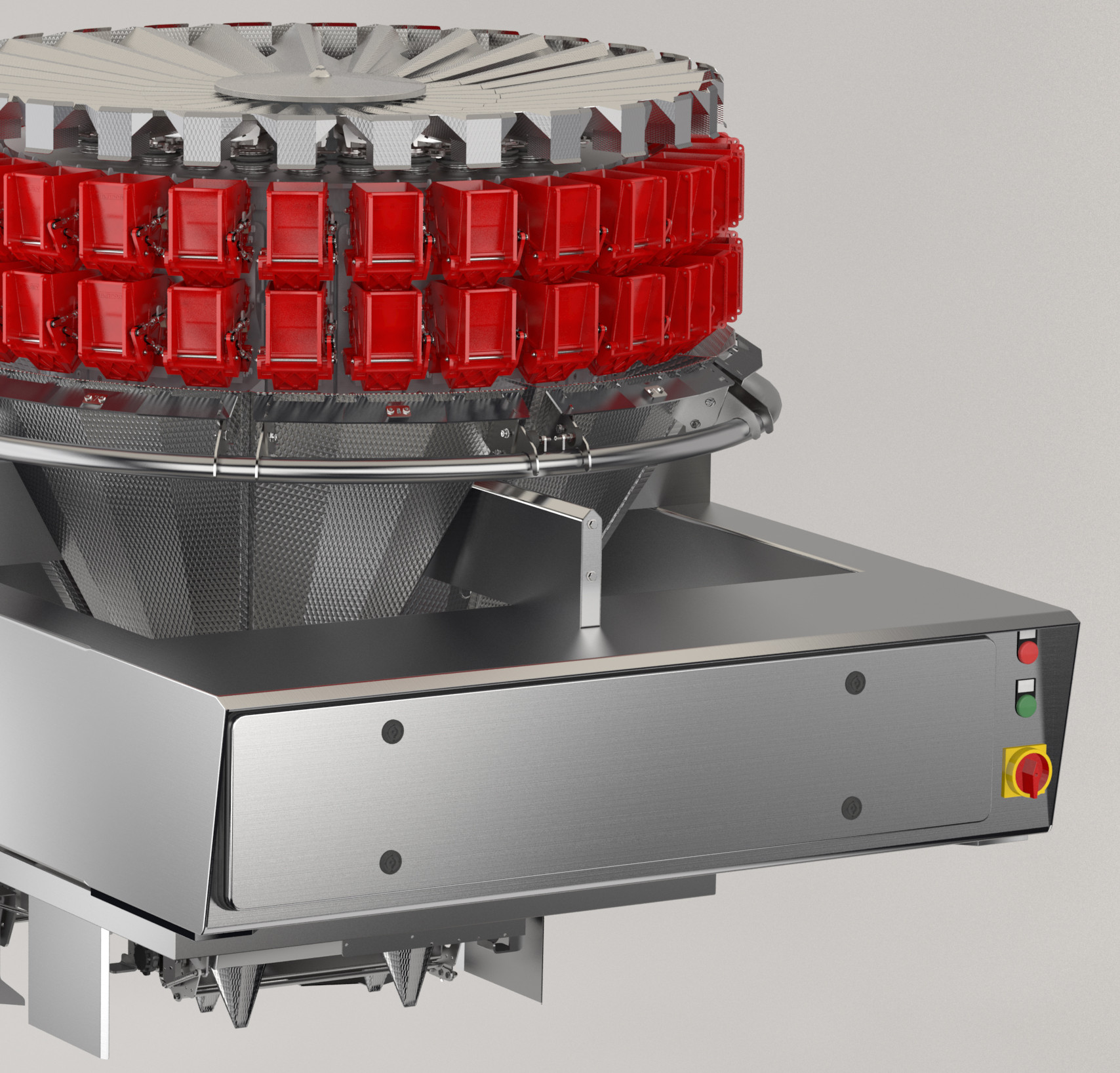

Multihead Weigher

The use of multihead weigher machines

Multihead weigher machines are convenient, factory-based devices that help firms accurately and consistently weigh a wide variety of product components before packing. Used primarily in the food and drink industry, weighing machines also find applications in the pharmaceutical, pet food, and petrochemical sectors. Ultimately, weighing machines help brands improve profitability and hygiene, and assign components to products with greater accuracy.

Industries we can help with

Food And Drink

Food processing plant design consultants can help you improve your plant’s energy efficiency, increase your rate of production, reduce lead times, and achieve 100 percent food safety compliance. However, they are also essential when you want to expand your operations.

Pet Food

Setting up a pet food production line is similar to a human food production line. However, as you might expect, there are some differences.

Pharmaceutical

Pharmaceutical engineering and plant design consultants help you expand pharmaceutical production lines in factories more efficiently and effectively. Their work includes regulatory compliance, validation, and implementing logistics services for maintenance and systems management. Most consultants assist firms from the initial concept stage onwards, guiding them through every step of the plan.

Petrochemical

Using an outside consultant for your petrochemical engineering projects can help you to maintain safety, efficiency and productivity like never before, all while minimising your spend and controlling your budget for your petrochemical plant construction.

Types of multi-head weighing machines

Multi-head weighing machines come in various types depending on the application.

Dry food weighing

Dry food weighing tends to be among the easier weighing applications for multi-head weighing machines. Dry food is, generally, a robust product, and will not stick to the sides of the hopper. Slopes can be set at standard angles to ensure delivery of products to packaging or conveyor belts, and changeover maintenance is minimal.

High-accuracy weighing

Some brands require low food weight errors. Therefore, manufacturers have introduced a range of more sophisticated multi-head weighing machines to the market with improved performance specifications. These machines have enhanced weighing accuracy, leading to more finished packs per kilogram of product, fast calculation time, and vibration systems that self-tune to optimise product flow. Simple cleaning protocols also minimise downtime.

Screw feed weighing

Some food items are more challenging to handle than others. Sticky, long, or wet items may struggle to pass through traditional hopper and chute components and could lead to clogging.

Therefore, some weighing machines come with screw-feed mechanisms. These help to cut down on manual labour requirements while also maximising product yield by ensuring that the majority of product passes into pack fill stations.

To improve hygiene, many multi-head weighing machines feature easy-to-sterilise hoppers and waterproof, wash-down designs. Some machines are specifically designed for high-volume, infrequent changeover conditions.

Low Weight Target Applications

Linear weight multihead weighing machines are suitable for mixed weighting and specifically designed for low target weight applications, for instance, in the pharmaceutical sector. Machines feature superior product flow and high performance, even when operating in small spaces.

Multi-component Systems

Lastly, some products have many components that require packing in the exact layout determined by the packaging, without loss, damage, or splashing outside of the intended zones.

Multihead weighing machines cater to this requirement with innovative designs that help to deliver ingredients to the right location, in the right quantity. Systems are programmable and ideal for ready meals, salads, and snack boxes.

The Benefits Of Multihead Weighing Machines

The benefits of multihead weighing machines are considerable.

- Faster product preparation and packing: Quality multihead weighing machines let you boost production speed, allowing you to ship products faster when you receive large orders from clients

- Efficient use of ingredients: Multiple components inside multihead weighing machines, such as radial troughs and anti-floor vibration, reduce wastage, ensuring that the maximum amount of the ingredient reaches the pack

- Greater accuracy: Reduce costly product pack size errors by carefully measuring weights so you can hit your exact targets before packing

- Long-lasting equipment: Get heavy-duty machinery that is tough, reliable, waterproof, and engineered to last.

Mechanical and Electrical Services

Mechanical and Electrical Services  Lift and Shifts Works

Lift and Shifts Works  Construction

Construction